WELLPOINT SYSTEM

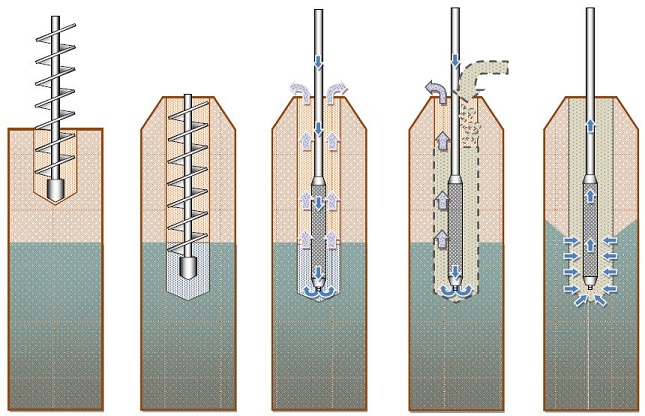

The drainage with wellpoint system is used in all those soils that are permeable due to porosity, such as gravel, sand, silt and clay. In its most schematic form, the system consists of a series of wellpoints installed in on ground where the water table must be lowered. These are connected to each other and to a high vacuum gradient pump through a series of manifolds, fittings and connection joints.

The system is installed by drilling holes in the ground and driving the tips with a jetting pump that literally “washes” the ground, allowing the system to work at its best. In the case of clayey / loamy soils, it is necessary to create a pre-filter chamber with sand which will constitute a cavity to protect the filter from clogging and will create a drainage communication in the stratified soils.

In peculiar situations, we are able to offer our customers some alternative ways to install the wellpoint system without removing any material.

- with water only, in a “self-jetting” mode

- by direct vibro-insertion

- by vibro-driving with the use of a shirt

- with mechanical punching machines

IN-LINE WELLPOINT

It is normally used with pipelines (aqueducts, sewers, methane pipelines…) and often in a revolving mode. It can be single-line, if the excavation width allows it, or double-line if the excavation width requires it.

PERIMETER WELLPOINT

In particular construction sites, where the excavation area is high, it is necessary to proceed with a wellpoint line that runs along the entire perimeter of the excavation (leaving an opening for vehicles access). This technique serves to dry the area inside it and to intercept the flow of water which, otherwise, would infiltrate the excavation again. A so-called “hydraulic barrier” is then formed to allow to dry the water present, and to block that which, otherwise, would return to the excavation.

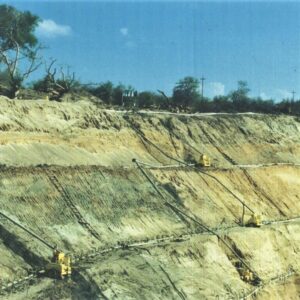

WELLPOINT WITH STEPS

WELLPOINT WITH STEPS

There is a limit to the maximum depth up to which the wellpoint system can work. When there is the need to reach high excavation depths with groundwater abatement greater than 5 – 6 m, it is necessary to resort to several concentric rings of wellpoints using the so-called step technique. The interventions in these cases are distributed in phases and each excavation is followed by the installation of systems at a different altitude.

WELLPOINT IN PROGRESS

In the case of construction sites in progress, it is possible to “build” the wellpoint system while the works proceed. This type of system is defined in a “revolving” mode. The number of pumps used remains the same, but they are moved forward so to follow the progress of the works. Using this method, it is important to have the right coordination between driving times, drainage ones and site progress. The executive methods remain the same as those of the plants previously described, depending on the ground and excavation area.